FRAMES AND FOUNDATION:

The beeswax comb in

a modern Langstroth removable frame

hive begin with a foundation. The purpose of the foundation is to give

the bees a pattern for placement of the comb they build. It isn't that

bees can't build comb without it but their naturally constructed comb

is irregular shaped and fragile.

The more durable approach developed over the years is to provide foundation

with a wood frame consisting of a top and bottom bar together with two

end bars in which the bees build their comb. This results in combs which

can be handled easily and from which honey can be extracted without destroying

the delicate wax comb. Thus, the frames and their comb is reused year

after year.

In a more primitive

hive arrangement the bees construct their comb simply from a top bar without

anything else. Known as a "top bar" hive, this technique is

still used in some third world countries because it is cheaper and easier

to construct. Without the support of a frame around the comb it is fragile

and the honey can not be harvested without destroying the comb.

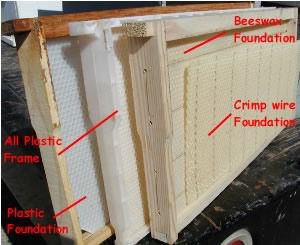

The three frame types in common use today are shown in fig. 7. These are

new frames with foundation that has not yet been drawn out into comb by

the bees. Although difficult to see in the pictures, all foundation is

dimpled or indented with the six sided honey comb pattern from which the

bees will draw out (construct) the comb.

WAX FOUNDATION:

Traditionally, foundation is made from a thin sheet of beeswax about

1/16" thick which is cut to size and formed through a set of special

rollers that indent the honey comb pattern on it. Since this thin beeswax

foundation is not particularly sturdy, the wood frame is wired from end

bar to end bar and the wires are then imbedded into the wax to support

it. These cross wires can be seen in the pictures at right (fig 7, 8 &

9) of the frame with wax foundation. A special tool with a star shaped

metal wheel is used to press or imbed the wire into the soft wax. Note

the way the wire is strung through the holes in the end bar and tied off

on a small nail at the end. Although not done here, a refinement of the

cross wiring is to use small metal grommets in the holes on the end bars

to keep the fine wire from cutting into the wood.

Another improvement in wax foundation is the addition of "crimp wires"

(fig. 8) which are placed vertically in the wax foundation when it is

manufactured. While not part of the frame shown, this loose sheet of foundation

shows the stiff steel wires formed or crimped into a slight zig zag pattern

that helps hold the wax together in conjunction with the cross wires.

The single advantage of wax foundation is that bees will draw it out quickly.

The disadvantages are it is labor intensive to assemble, never as rugged

as its plastic counterpart and more subject to mice damage as they can

chew holes through it.

PLASTIC FOUNDATION:

The more durable foundation is made of plastic. Since the plastic

sheets are thicker and more rigid, the indentations of the honey comb

are deeper and better defined. Most plastic foundation is coated with

a thin layer of beeswax during manufacture which helps attract the bees

to draw it out. It is sold both coated and uncoated, however, bees have

a hard enough time drawing out the best wax coated plastic foundation

and uncoated plastic is more difficult. Again, the benefit is that once

drawn out you have a frame with comb that will out last any thing else.

Figure 10 shows a frame which has been in service over 10 years.

Plastic foundation is sold under trade names such as PlastiCell and RiteCell.

An early version of the plastic foundation sold under the name Duriglt

used a thin smooth sheet of plastic coated with a heavier layer of beeswax

with the comb indentations. The problem with this is that if the wax comes

off for any reason the bees will do nothing with the remaining smooth

plastic surface.

A somewhat unique feature of the PlastiCell foundation is that the lower

two corners can be broken off as can be seen in the pictures leaving an

opening for bees to move from one side of the frame to the other.

The major advantage of the plastic foundation is its strength. This is

a real benefit in frames used for honey extraction, as the wax foundation

will often blow out in the extractor due to the weight of the honey.

PLASTIC FRAME:

The ultimate labor

saver - assembly not required! Beekeepers either love or hate them. The

only drawback to these frames is burr comb. Burr comb is comb the bees

build for no reason other than to stick things together and for some reason

the bees want to glue plastic frames together - big time. They do this

between the top bar on the lower box and the bottom bar on the box above

it making the boxes almost impossible to separate at times. A hardened

steel hive tool was once broken prying apart boxes with - yes, plastic

frames.

This is much more of a problem with these frames than with wood. The bees

seem to be more comfortable with wood than plastic. This can be seen in

fig 11. Notice the heavy burr comb visible on the plastic top bar of the

plastic frame in the lower portion of the picture compared to that of

the wood top bars in the upper portion.

This comb is drawn on PlastiCell and is over 10 years old.