|

|

|

AN EXCEPTIONAL YEAR - SUN FLOWERS IN SEPTEMBER Two things make a really good honey year in our part of the country. First, is a wet Spring - the wetter the better. One of the best honey years we ever had was 1992 when it was so wet farmers couldn't get in some fields to plant their crops until May. The second thing, is getting those "out of character" rain showers in July or early August to bring on the Sun Flowers in September. You can see the results in these four pictures from this year! This part of Idaho is essentially a desert - receiving only about 11" of annual rainfall. If it weren't for irrigation from the surrounding mountain reservoirs the summers would be so dry there wouldn't be any agriculture or honey production to talk about. But the wild Sun Flower doesn't depend on irrigation like so many of our other wild flowers do, it's a lone survivor that flourishes when there is an exception to the rule of dry summer months. When it happens, as it did this year, we are rewarded with an abundant sun flower crop. This year, the main honey flow shut off in mid August as it usually does when most of the vegetation dries up. These pictures taken around the first week in September show what a few showers in July can do. A week or so after they were taken, the honey supers were removed to harvest the surplus honey, leaving just the bottom two boxes. Sun Flowers come a little late to help much with honey production, but they are a timely source of pollen and nectar for the bees this time of year. With the winter approaching, the bees need to keep their two boxes full with honey as they prepare for winter and the Sun Flowers along with other late blooming plants help provide these winter stores. |

|

|

|

COMB

HONEY

|

|

Honey in the beeswax comb is the rawest form of honey you can get because it is simply removed from the hive and packaged for sale - totally untouched and unprocessed! Comb honey is a traditional favorite and this delicacy is still preferred by many people today. Bees make the beeswax from honey, thus it is not only eatable but also digestible. You simply eat the comb and all - swallow the wax or chew it like gum and spit out. We produce comb honey using the "Ross Round" system because, among other reasons, the finished packaging is so durable, attractive and practical. The plastic covers which go on after removal from the hive make it clean, easy to see and handle. Shown in Fig 1 on the left in the picture, is a round comb section with the covers in place. The completely finished product on the right includes a label. |

|

|

1.

Ross Round comb honey sections.

|

|

Comb honey, like all honey, is produced in a super, the extra box(s) added to the hive to collect surplus honey. However, instead of regular frames for extracting liquid honey, the comb honey super has plastic frames as seen in Fig 2 containing a thin sheet of pure beeswax foundation sandwiched between a split frame housing (the brownish part) holding four sets (pairs) of round white plastic rings. Four rings can be seen in the picture and the other four identical rings not visible are on the other side of the frame. When the comb honey super is placed on the hive, the bees draw out the foundation building the comb and filling it with honey after which the cells are capped when the honey is completely cured. |

|

2.

Comb Honey frame with plastic rings and beeswax foundation in place.

|

|

The production of attractive sections of comb honey is a learned art requiring a great degree of attention to detail. The hive or colony for comb honey production is managed through early spring by providing unrestricted space to give the queen plenty of room for brood production for build up of hive population before the honey flow starts. The comb honey super must be placed on the hive to concede with the start of the honey flow. If it is placed on the hive too early the bees have little motivation to build the comb and it can become discolored by the bees walking around on the foundation or partially built comb causing travel stains. But when placed on the hive just after the honey flow starts, the bees build the comb immediately because it is needed to contain the abundance of honey. The colony is reduced to a single deep box when the comb honey super is added further restricting the available space in the hive providing additional urgency to draw out the comb. In this manner, the comb is built and filled rapidly to minimize the likelihood of staining or discoloration of the wax comb. Fig 3 shows the finished comb honey super being removed from the hive just after the fume board was removed. The fume board is used to remove the bees from the super and is still visible on the second hive to the right in this picture. Plastic frames described earlier are can be seen in Fig 4 from the bottom of the super and in Fig 5 from the top. There was a "Comb Honey" era from the period of around 1880 to 1920 during which time most beekeepers produced comb honey. Consumers in that time preferred comb honey to liquid honey because they understood it was a pure, natural product. As late as 1950 some beekeepers were still producing only comb honey but, because it is cheaper and easier to produce liquid honey, comb honey production has declined and has almost become a thing of the past. Today, comb honey has become somewhat of a delicacy but, those who prefer "raw" honey in the strictest sense of the word will find no other source of honey that is literally untouched by anyone other than the bees. |

|

|

3.

Removing the comb honey super.

|

|

|

|

|

4.

The bottom of the comb honey super - note the burr comb.

|

|

|

|

|

5.

Comb honey super after removal of the bees.

|

|

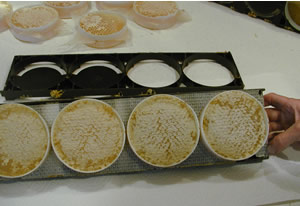

Only after the comb honey super is removed from the bee hive can the sections be evaluated by disassembling the frames. Shown in Fig 6, these sections are filled without any open cells or objectionable stains. Note the arrangement of the comb sections - each one facing a "blank" end that limits the depth of the comb built by the bees when the frames are assembled together.

Once the frames are removed from the box, the frame halves can be split as seen in Fig 7. Note the original thin sheet of beeswax foundation is still connecting the individual sections. This excess is trimmed around the outside of comb sections prior to placing the plastic covers. Separate comb sections with the excess foundation material not yet trimmed are visible in the background. |

|

6.

Finished frames being removed from the comb honey super.

|

|

|

|

|

7.

Comb sections with the frame half removed.

|